Chii chinonzi Magnetic Coupling?

Magnetic Couplingimhando nyowani yekubatanidza inobatanidza iyo prime mover uye muchina unoshanda kuburikidza neiyo magineti simba remagineti anogara. Magnetic Coupling haidi yakananga mechini yekubatanidza, asi inoshandisa kudyidzana pakati peasingawanzo pasi magineti echigarire, uchishandisa iyo magineti kupinza imwe nzvimbo yenzvimbo uye hunhu hwezvinhu zvekushandisa kufambisa magetsi emagetsi.

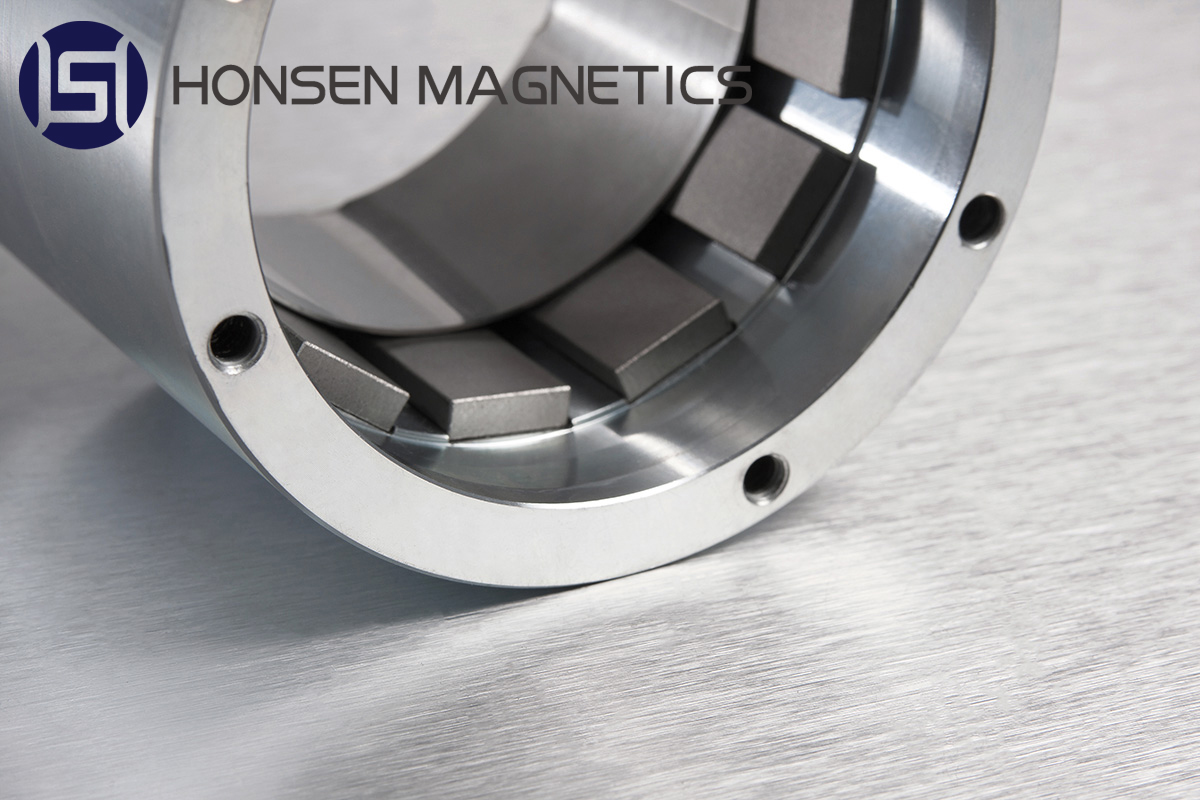

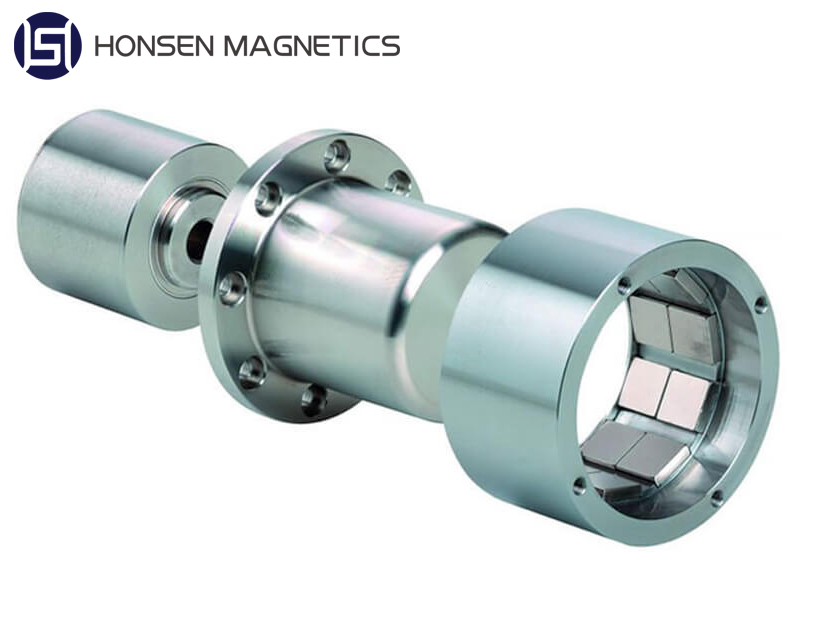

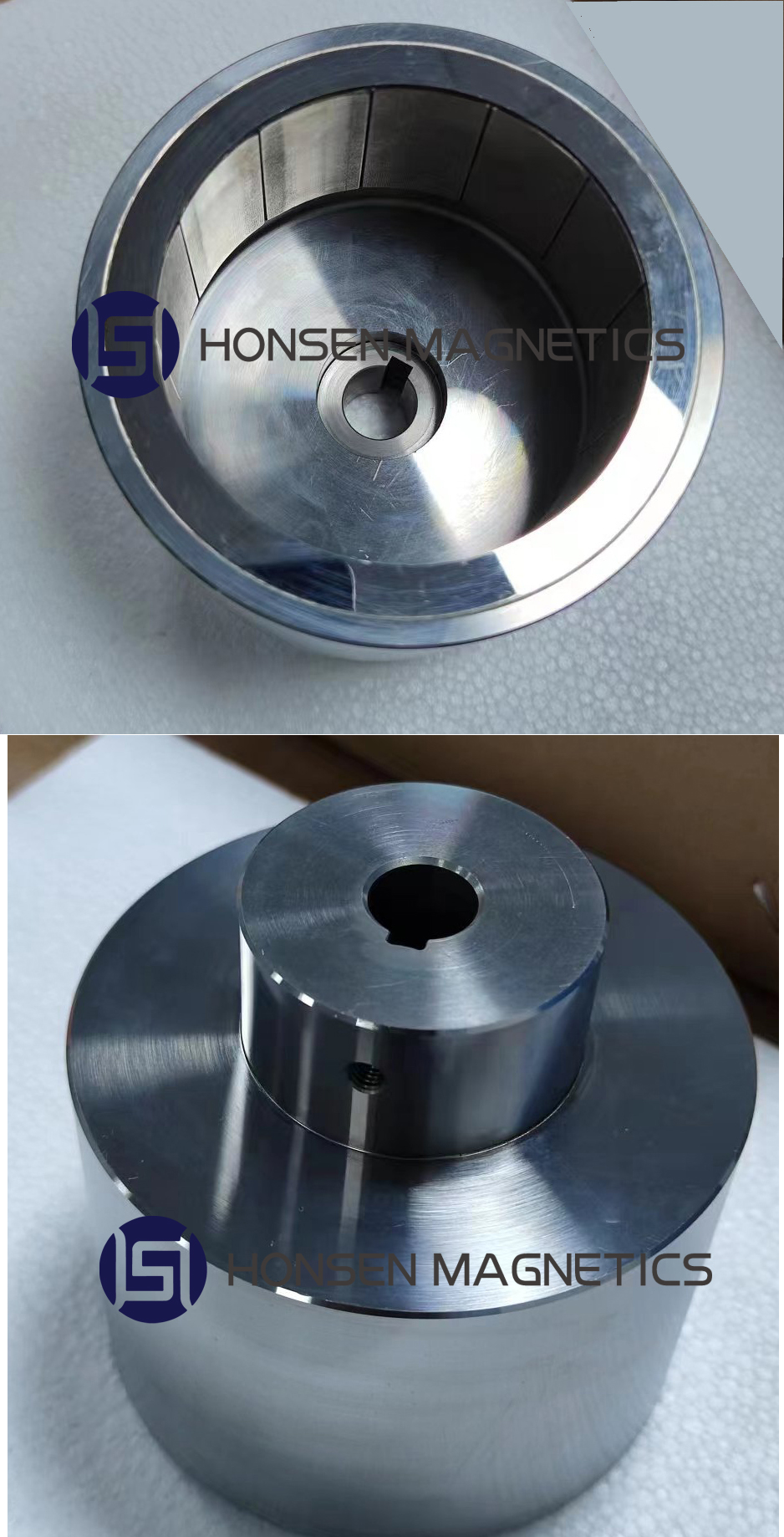

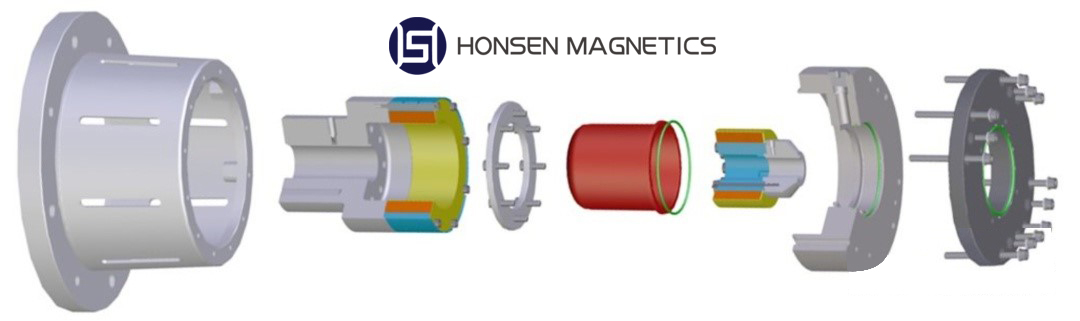

Iyo magnetic coupling inonyanya kuumbwa nekunze rotor, rotor yemukati, uye yekuisa chisimbiso (kuzviparadzanisa sleeve). Iwo maviri rotor akaparadzaniswa nekavha yekuzviparadzanisa pakati, ine magineti yemukati yakabatana nechikamu chinotyairwa uye magineti ekunze akabatana nechikamu chesimba.

Iyo magnetic couplings inogona kugadziriswa. Magineti echigarire anowanzo shandisaSmCokanaNdFeB magineti, uye giredhi chairo rinoda kutariswa zvichibva pane tembiricha yekushanda, nharaunda yekushanda, uye torque yekubatanidza. Iyo goko rinowanzo gadzirwa nesimbi isina tsvina (Q235A, 304/316L).

Iyo magineti couplings inogona kuiswa kune akasiyana marudzi emapombi uye musanganiswa senge screw pombi, giya pombi, nezvimwe. Iwo magineti couplings anogona kushandiswa kuwana sealless pombi kudzivirira kukuvadzwa kunokonzerwa nekuora kwemvura midhiya inopfuura nepashaft zvisimbiso. Magnetic Couplings anogona zvakare kuiswa kune emagetsi submersible zvishandiso, senge pombi inodzika, pamwe neakasiyana siyana tekinoroji uye yakadzika-gungwa mafuta ekuchera rigs.

Kurongwa kweMagnetic Couplings

- Yakakamurwa kuita magineti kutapurirana, yakakamurwa kuita synchronous kutapurirana (planar uye coaxial), eddy ikozvino kutapurirana, uye hysteresis kutapurirana;

- Yakakamurwa kuita mutsara inofamba, inotenderera inofamba, uye inoumbwa inofamba yakavakirwa pamaitiro ekufambisa kwekufambisa;

- Yakakamurwa kuita akasiyana zvimiro, inogona kukamurwa kuita cylindrical magineti couplings uye flat disk magnetic couplings;

- Yakakamurwa kuita misimboti dzakasiyana dzekushanda, inogona kukamurwa kuita synchronous magineti coupling uye asynchronous magineti coupling.

-Akakamurwa kuita dhizaini yemagineti echigarire, anoiswa mugap rakaparadzirwa mhando uye akasanganiswa dhizaini rudzi.

Ndeapi makuru tekinoroji paramita eMagnetic Coupling?

Paunenge uchisarudza magineti couplings, zvinodikanwa kunyatso funga zvinhu zvakaita senge mamiriro ekushandisa, mota uye mutoro hunhu, uye zvinodikanwa zvebasa, uye sarudza yakakodzera tekinoroji paramita uye masisitimu ekugadzirisa.

Magnetic coupling chishandiso chinotapurirana chinoshandisa magineti torque kufambisa torque, uye iwo makuru ehunyanzvi maparamita anosanganisira zvinotevera zvinhu:

- Yakakura torque: inomiririra iyo yakanyanya torque iyo magineti coupling inogona kubuda. Iyi parameter ine hukama zvakanyanya nemamiriro ekushandisa, uye kazhinji, zvinodikanwa kusarudza iyo yakakodzera yepamusoro torque kukosha zvichienderana nezvinodiwa chaizvo.

-Kushanda kumhanya: inomiririra yakanyanya kumhanya iyo iyo magineti coupling inogona kumira. Iyi parameter inokanganisa huwandu hwekushandiswa kwemagineti couplings, uye kazhinji, kukurumidza kushanda kunogona kuzadzisa zvinodiwa kunofanira kusarudzwa.

-Kurasikirwa kwesimba: Zvinoreva kune simba rinotorwa nemagnetic coupling kushandura magineti kuita simba rekupisa kana mamwe maitiro ekurasikirwa. Iyo diki simba rekurasikirwa, iyo yakakwirira kushanda kweiyo magineti coupling, uye zvigadzirwa zvine yakaderera kurasikirwa simba zvinofanirwa kusarudzwa zvakanyanya sezvinobvira.

Ndeapi maitiro ekuita kweMagnetic Couplings?

Magnet Coupling imhando yekubatanidza yakavakirwa pakufambiswa kwemagineti simba kuburikidzazvachose magineti zvinhu, iyo ine zvinotevera maitiro ekuita:

-Kunyanya kutapurirana zvakanaka: Kuenzaniswa neyechinyakare couplings, magineti couplings anoshandisa zvechigarire magineti zvinhu semagineti midhiya, zvichikonzera kushanda kwepamusoro kutapurirana, kusvika pamusoro pe99%.

- Yakakwira torque density: Nekuda kweiyo yakakwira magineti simba chigadzirwa chekusingaperi magineti zvinhu, magineti couplings ehukuru hwakafanana anogona kumira torque yakakura kana ichienzaniswa neyechinyakare couplings.

- Yakarurama torque kufambisa: Iyo yekutapurirana torque yeiyo magineti coupling ine mutsara ine hukama nekumhanya kwekuisa, saka inokwanisa kunyatso kufambisa torque inosangana nezvinodiwa mukushanda kwekuita uye ine simba rekuchinja.

- Yakasimba magineti kugadzikana: Zvisingaperi magineti zvinhu zvine kugadzikana kwakasimba uye magineti kudzoreredza. Kunyangwe mukupisa kwakanyanya uye humidity nharaunda, hapazovi nekuchinja kwemagineti, saka ine hupenyu hurefu hwebasa.

- Chengetedzo yesimba uye kuchengetedza kwezvakatipoteredza: Nekuda kwekushandiswa kwemagineti kufambisa mune magineti couplings, zvichienzaniswa neyakajairwa mechanical transmissions, haiburitse kukweshera kwesimba, kurasikirwa nekupisa, uye kusvibiswa kweruzha, nekudaro kuve nekuchengetedza simba kwakanaka uye kuchengetedza kwezvakatipoteredza.

Sei tichigona kuita Zvirinani

Honsen Magneticsinyanzvi mukugadzira nekugadziramagnetic magunganouye magnetic couplings. Chikwata chepakati chine zvizere zvemagineti wedunhu dhizaini mainjiniya uye madhizaini ekugadzira mainjiniya. Mushure memakore ekubatanidzwa kwemusika, isu takagadzira timu yakakura: kubva pakugadzira, uye sampling kusvika batch kuendesa, tine zvishandiso uye zvigadziriso zvemichina zvinokwanisa kurarama nekugadzirwa kwakawanda, mamwe acho akagadzirwa uye anogadzirwa isu pachedu, Takadzidzisa boka. yevashandi vane ruzivo rwekugadzira.

Isu hatingope IMWE-KUMIRA-SERVICE yedhizaini sampuli batch odha yekutumira asi zvakare kuyedza kuenderana mune batch zvigadzirwa. Isu tinovavarira kuramba tichivandudza uye kuderedza kupindira kwevanhu zvakanyanya sezvinobvira.

Zvakanakira zvedu mukugadzira Magnet Couplings:

-Kuziva nemhando dzakasiyana dzemagineti, inokwanisa kuverenga nekugadzirisa magineti maseketi. Tinogona kuverenga quantitatively iyo magnetic circuit. Semuenzaniso, kana mutengi ataura torque yekubatanidza magineti echigarire, tinogona kupa iyo yakakwana uye yakaderera-yemutengo mhinduro zvichienderana nemhinduro dzekuverenga.

-Ane ruzivo Mechanical mainjiniya, iyo mechanical properties, dimensional tolerances, uye zvimwe zvinhu zvemagnetic magunganozvakagadzirirwa uye kuongororwa navo. Ivo zvakare vanogadzira yakanyanya kunaka kugadzirisa hurongwa zvichienderana nezviwanikwa zvemuchina chirimwa.

-Kutsvaga kuenderana kwechigadzirwa. Kune mhando dzakasiyana dzemagineti zvikamu uye maitiro akaomarara, senge gluing process. Manual gluing inogona kusiyana pamunhu nemunhu, uye huwandu hweglue haugone kudzorwa. Iyo otomatiki yekuparadzira michina pamusika haigone kuchinjika kune zvigadzirwa zvedu. Isu takagadzira uye kugadzira sisitimu yekuparadzira yekudzora otomatiki kubvisa zvinhu zvevanhu.

-Vashandi vane hunyanzvi uye inoenderera innovation! Iko kuungana kwemagineti couplings uye magineti magungano kunoda vane hunyanzvi magungano vashandi. Isu takagadzira uye nekugadzira akawanda akasiyana uye anoyevedza zvigadziriso uye maturusi ekudzikisa kuwanda kwevashandi, kunatsiridza mashandiro, uye nekuwedzera kuve nechokwadi chekuenderana kwechigadzirwa.

Zvishandiso zvedu

Kuti tinozviwana sei

Kuteerera kune zvinodiwa nevatengi

Kuti tinzwisise zvizere zvinangwa zvemutengi, isu hatitarise kwete chete akakosha ekuita zviratidzo zvemagineti maassemblies asiwo zvinhu zvakaita senzvimbo yekushanda, nzira dzekushandisa, uye mamiriro ekufambisa echigadzirwa. Nekuwana kunzwisisa kwakadzama kwezvinhu izvi, tinokwanisa kunyatsogadzirira chikamu chinotevera chekugadzira sampling. Iyi nzira yakazara inovimbisa kuti dhizaini yedu inoenderana zvakakwana nezvinodiwa nemutengi uye inovimbisa kuita kwakaringana mumamiriro ezvinhu epasirese.

Computational Design Model

Batsira mukuverenga uye kugadzira magineti maseketi zvichienderana nezvinodiwa nevatengi. Kutarisisa kwekutanga kwekugadzirisa uye kugadzirisa maitiro, uye zvichibva pane yedu ruzivo uye kuverenga mhinduro, kurudzira mazano ekuvandudza edhizaini isina kukwana yemutengi. Pakupedzisira, svika pachibvumirano nemutengi uye usayine odha yemuenzaniso.

Chekutanga, zvichibva pane zvakaitika kwatiri uye CAE-yakabatsirwa kuverenga, iyo yakakwana modhi inowanikwa. Mapoinzi akakosha eiyo modhi ndeyekuti huwandu hwemagineti hunofanirwa kudzikiswa uye chimiro chemagineti chinofanirwa kunge chiri nyore kugadzira. Pahwaro uhwu, mainjiniya anonyatso funga chimiro chemuenzaniso kuti zviite nyore kugadzirisa nekuunganidza. Ronga maonero edu uye kutaurirana nevatengi, uye pakupedzisira kusaina maodha emuenzaniso.

Gadzira maitiro uye sampuli

Gadzira maitiro akadzama uye wedzera kunaka kwekutarisa mapoinzi. Iyo dhizaini yekuparara kwechigadzirwa cheiyo magineti mudziyo yatanga kugadzirwa.

Zvigadziriso zvekugadzira: 1. Ita shuwa chimiro, chinzvimbo, uye dimensional kushivirira kwezvikamu; 2. Inoshandiswa pakuyera midziyo kuti uone kunaka.

Uyu muenzaniso wenzvimbo yedu yekuyedza yakasarudzika. Mushure mekusaina chiyero chemuenzaniso, zvichibva pakugadziriswa uye maitiro egungano, isu tinofanirwa kuvandudza maitiro akadzama uye nekuwedzera kutariswa kwemhando mumatanho akakosha. Panguva imwecheteyo, tinogadzira zvigadziriso zvekushandisa. Panguva ino, chishandiso chinoshandiswa kuve nechokwadi cheiyo geometric uye dimensional kushivirira kwezvikamu uye chigadzirwa chose, uye nekuyedza paramende kuona kuti zvigadzirwa zvedu zvinogona kuongororwa nekukurumidza uye nemazvo mumabheji anotevera.

Bulk production control

Mushure mekugamuchira maodha akawanda, ronga vashandi kuti vashande, kuronga zvine musoro nzvimbo dzekushandira uye maitiro, uye kana zvichidikanwa, gadzira yakasarudzika maturusi ekugadzirisa kuderedza kuwanda kwevashandi uye kuve nechokwadi chekuenderana mukugadzirwa kwebatch.

Magnet ekubvisa michina

Kubatanidza magineti echigarire, magineti emota, uye mamwe magineti magineti anoda kuti magineti aitwe magineti isati yasangana. Manual disassembly yemagineti haishande, uye chinonyanya kukosha ndechekuti zvinorwadza kubvisa magineti neminwe yako kwenguva yakareba. Naizvozvo, isu takagadzira uye kugadzira iyi diki midziyo kuti ibvise zvachose kurwadziwa kwevashandi uye kunatsiridza kugona.

Automatic gluing midziyo

Mazhinji magineti couplings uye zvikamu zvinoda kushandiswa kweglue kubatanidza magineti akasimba uye zvimwe zvinhu pamwechete. Kusiyana nemanyorero egluing, huwandu hweglue haugone kudzorwa. Isu takagadzira uye kugadzira otomatiki gluing michina yakanangana nezvigadzirwa zvedu, iyo inoshanda zvakanyanya uye inoshanda zvichienzaniswa nemidziyo inotengeswa pamusika.

Automatic laser welding

Zvizhinji zvezvigadzirwa zvedu zveodha zvinoda laser welding yezvishandiso zvekuisa chisimbiso (zvimwe zvemagineti zvinoda kuti magineti avharwe zvizere). Mune welding chaiyo, iyo workpieces ine tolerances uye kune thermal deformation panguva yewelding; Izvo hazvishande kupinza nemaoko mahombe akawanda eodha. Isu takagadzira uye kugadzira akawanda ehunyanzvi zvigadziriso kuti tigonese vanotanga kukurumidza kutanga.

Isu tine ruzivo rwakakura mukutonga kwekugadzira, uye isu tinofanirwa kuwana quantifiable control mumatanho ese kuti tive nechokwadi chekuenderana mubatch yega yega yezvigadzirwa.

KUPAKA & KUSVIRA

Q&A

Q: Pane mifananidzo here?

A: Isu takagadzirisa uye takagadzira akateedzana zviyero zvekubatanidza, uye vatengi vanogona kugadzirisa zvinoenderana neizvi. Uye isu tinogamuchirawo vatengi vedu kune chero mapurojekiti akagadziridzwa.

Q: Ndeipi sampuli, mutengo, uye nguva yekutungamira?

A: Pakutanga kweiyo magineti yekubatanidza purojekiti, sampuli yekuyedza inogara ichidikanwa, saka tinogamuchira maodha emuenzaniso. Nekudaro, kuti titarise vatengi vane batch vavariro, isu tichachaja yakakwira sampuli mubhadharo. Tichachaja mari yemuenzaniso kubva pa3000 kusvika pa8000 yuan ye torque kubva pa0.1 Nm kusvika 80 Nm, uye nguva yekuendesa kazhinji mazuva makumi matatu nemashanu kusvika makumi mana.

Q: Zvakadini nehuwandu MOQ uye mutengo?

A: Zvichienderana nekuoma kwekugadzirisa, ita mitongo yakanangwa uye makotesheni.

Q: Iwe une chero inventory?

A: Magnetic couplings anonyanya kugadziriswa. Semuenzaniso, kana vatengi vachida maburi akasiyana-siyana, isu tinofanirwa kugadzirisa zvakare zvikamu, kuti tisatore zvigadzirwa zvakapedzwa. Zvese zvakagadzirirwa kugadzirwa, hapana inventory.

Q: Ko magineti couplings anorasikirwa nemagineti kuita?

A: Magnetic couplings anoshandisa magineti echigarire kufambisa torque pasina mapundu. Kana magineti echigarire adzima kana kurasikirwa nemafaro, kubatanidza magineti kunoshaya basa. Nzira huru dzekubvisa magineti dzemagineti echigarire dzinosanganisira tembiricha yepamusoro, kuzunguzika, reverse magnetic field, etc. Naizvozvo, yedu yemagineti coupling inofanira kushanda musynchronous state yemukati nekunze rotor. Kana mutoro wacho wakakurisa, rotor yekunze inodzokorodza reverse reverse magineti pane yemukati rotor, iyo iri nyore demagnetized, zvichiita kuti torque ideredze kana kukundikana zvachose.

Q: Chii chandinofanira kutarisisa pakuisa magineti coupling?

A: Magnetic coupling is non-contact transmission, ine imwe gap pakati pekunze rotor uye sleeve yekuzviparadzanisa, pamwe chete nepakati pekuparadzanisa sleeve uye rotor yemukati, zvakanyanya kuderedza kuoma kwekuisa. Nekudaro, iyo madziro emadziro eiyo sleeve yekuzviparadzanisa yakaonda kwazvo, uye kana ikadhumhana nezvimwe zvikamu kana zvimedu zvakaoma panguva yekushanda, inokuvadza sleeve yekuzviparadzanisa uye inotadza kushanda sechisimbiso. Naizvozvo, zvinodikanwa kuve nechokwadi cheimwe dhigirii ye coaxiality zvinoenderana nekubvumidzwa kwakasiyana.

Q: Ungasarudza sei muenzaniso?

A: Chekutanga, tarisa torque yediki coupling zvichibva pane yakayerwa simba uye yakayerwa kumhanya kwemota. Iyo yakaoma yekuverenga formula ndeyekubatanidza torque (Nm) = 10000 * mota simba (kW) / mota kumhanya (RPM); Chechipiri, zvinodikanwa kuti unzwisise tembiricha yekushanda, kudzvanywa kwekushanda, uye yepakati anti-corrosion. Yedu yemagineti yekubatanidza inoda kumhanya isingasviki 3000RPM uye kushanda nesimba kuri pasi pe2MPa.

Q: Ko chigarire magineti coupling inoshanda sei?

A: Magnet Couplings anowanikwawo mune dzakasiyana siyana zvimiro mafomu. Yedu yekusingaperi magineti couplings anoshandisa musimboti wemagineti akasimba anokwezvana kune asiri ekutapurirana. Inoumbwa nemarotor emukati nekunze, akaunganidzwa nemagineti akasimba. Iyo mota inotyaira iyo yekunze rotor kutenderera ichiendesa kinetic simba kune yemukati rotor kuburikidza nemagineti wedunhu remukati nekunze rotor, zvichiita kuti rotor yemukati itenderere synchronously. Iyi mhando yemagineti yekubatanidza inowana static chisimbiso nekuda kwekushaikwa kwekubatana kwakaomarara pakati pemukati nekunze ekufambisa shafts uye inoshandiswa zvakanyanya mukufambisa masisitimu ekuora, chepfu, uye kusvibisa zvinwiwa kana magasi.