Magnetic formwork systemsinogona kubatsira kuwedzera kushanda zvakanaka, kunyaradza, uye kuchengetedzwa kwevashandi muindasitiri yekongiri yakasimbiswa. Indasitiri yekuvaka yakafanogadzirwa iri kukura zvishoma nezvishoma. Magnetic zvigadzirwa senge formwork masisitimu uye ferrule inopinza magineti anoshandiswa kuchengetedza ekuisa kune simbi formwork uchishandisa magineti, kubvisa kudiwa kwekuchera. Aya masisitimu ehunyanzvi akashandura kugadzirwa kwe precast kongiri zvinhu. Iyo magineti inogona kuiswa zvakananga mutemplate, iri nyore, inoshanda, uye yakagadzikana. Uchishandisa kunamatira kwakasimba kwakapihwa neiyo magineti block, iyo formwork yakanyatso kusungirirwa kune fomu, kuve nechokwadi kugadzikana kweiyo yakagadziriswa formwork system. Iko kusanganiswa kwesimbi formwork uye magineti blocks inobvisa chero mukana wekufamba sezvo kunyangwe kufamba kushoma kunogona kukonzera deformation yeformwork system. Magnetic formwork masisitimu ari mushandisi-ane hushamwari, anoda shoma yekudzidza curve, uye iwo anopa mupiro wakakura kukuchengetedza nekuchengetedza. Indasitiri yekuvaka yakagadzirwa yakagadzikana. Iine pry bar inoenderana, iyo formwork magineti anogona kusimudzwa zviri nyore kuti abvise nyore simbi formwork kubva pafomu. Sezvo magineti ari musimbi formwork grooves, kuvapo kwekongiri zvakasara kana tsvina hakuisi njodzi yekukuvadza kune formwork system.

Yedu precast kongiri fomu magineti ane simbi formwork uye akamisikidzwa magineti.

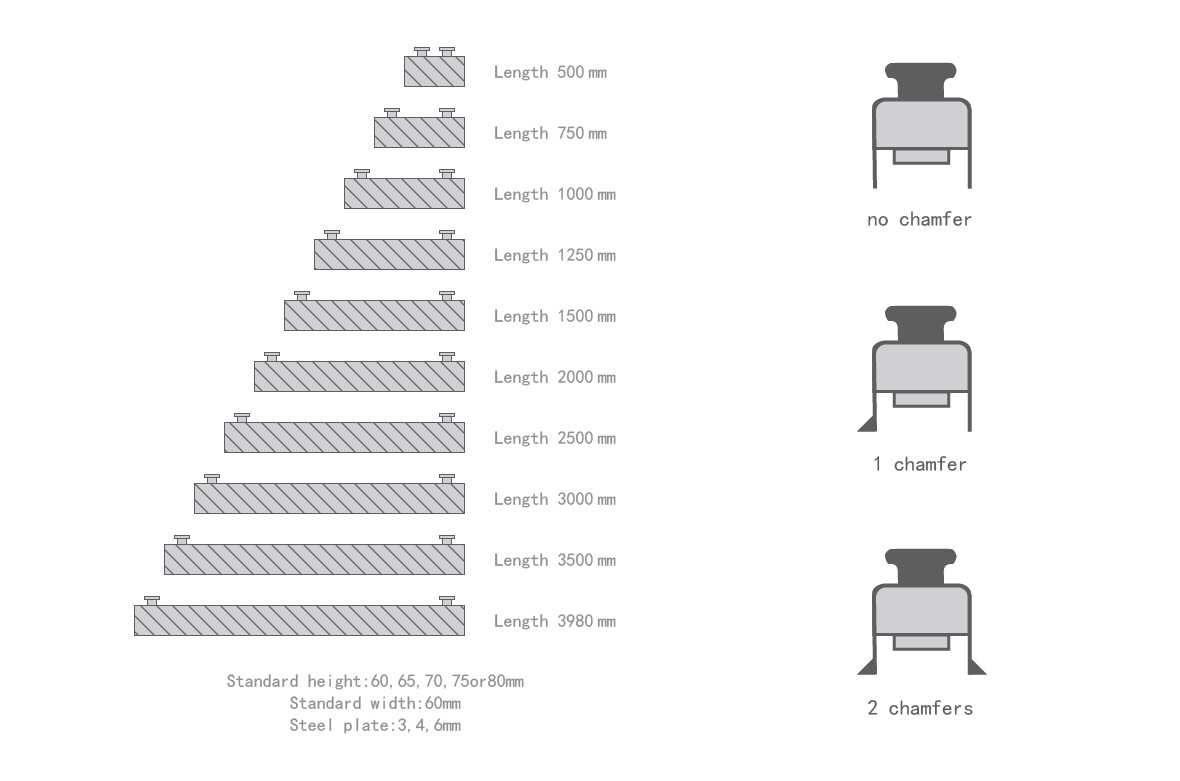

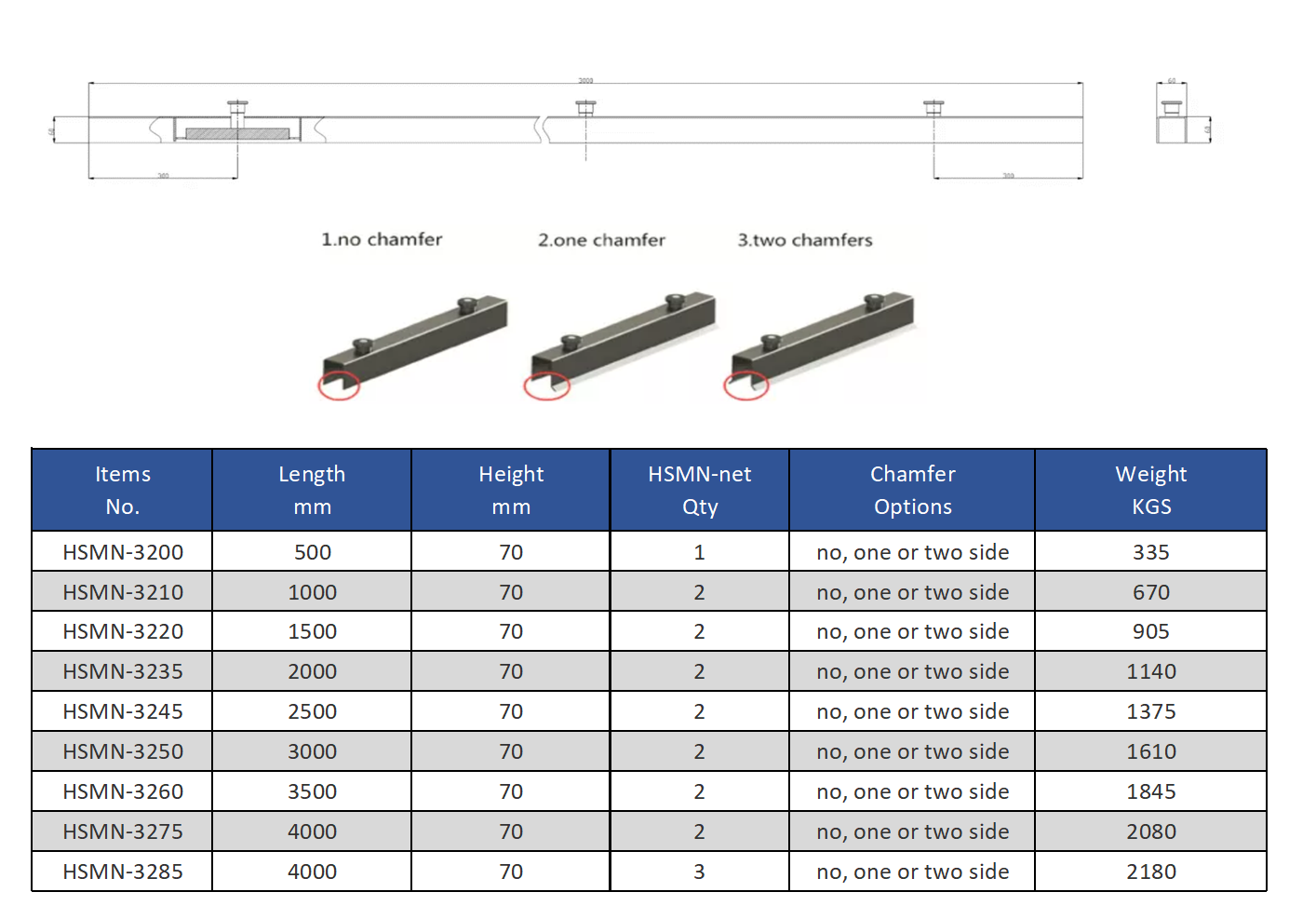

U-yakaumbwa kongiri formwork masisitimu akagadzirirwa kune chaiwo maratidziro. Vatengi vanogona kusarudza saizi yavanoda ine kana isina grooves uye kana vachida imwe chamfer, maviri chamfers, kana pasina chamfer.

Yedu yemagineti formwork masisitimu anogadzirwa nepamusoro-inoshanda magineti inoisa uye yepamusoro-mhando simbi. Iyo sisitimu inogona kuve yakashongedzerwa nemachamfers pamativi ese, kune rimwe divi, kana pasina chamfers zvachose.

Isu tinokwanisa kugadzirisa iyo system kuti isangane nehurefu chaihwo uye hurefu zvinodiwa nevatengi vedu. Isu tinogona kukubatsira iwe kuwana mhinduro chaiyo kune ako maindasitiri ekuvaka zvinodiwa.

- Easy kuwana

-Inoenderana nearipo formwork marobhoti kana anogona kuitwa activated nekudzvanya kwebhatani

- Mushandisi-ane hushamwari Inokwanisa kumira tembiricha yakakwira

- Corrosion resistant Yakakodzera kugadzira maseru mapaneru uye maviri madziro

-Custom saizi uye kureba zviripo pakukumbira

- Huwandu hwemagineti hunogadziriswa kune yega yega template basa

- Yakagadzirirwa kwenguva refu, yakavimbika, yakasimba kuita

-Kubvisa nyore nepry bar inoenderana

-Yakazara formwork system inopesana nekukuvara kubva kune kongiri zvakasara uye tsvina

-Sarudza kubva pa0 chamfer, 1 chamfer uye 2 chamfer sarudzo

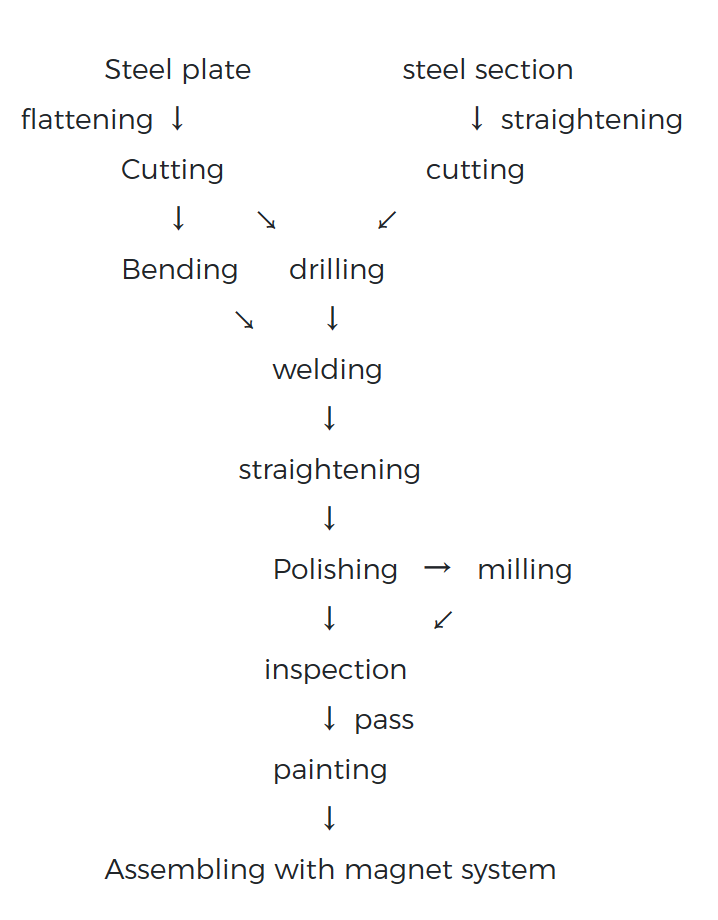

Iyo U-yakaumbwa kongiri formwork system inogadzirwa uchishandisa mahwendefa esimbi nerubatsiro rweyakasiyana yekupeta muchina. Iyo yekupeta michina ine basa rekugadzira sarudzo yekaviri-groove chamfer, single-groove chamfer, kana isina chamfer. Isu tinoshandisawo mawoko solder midziyo kune solder formwork magineti muhukuru pakati pe2-3 m. Zvivakwa zvedu zvekugadzira zvinokwanisa kugadzira template magineti ane hurefu hunodarika 100mm.

Pazasi pane tarisiro yeakakosha kubata kwatinoshandisa panguva yekugadzira kuti tive nechokwadi chehupenyu hurefu hwemagineti formwork masisitimu aunotenga kubva kwatiri. Isu tinoshandisa musanganiswa wealuminium alloy uye Stainless simbi yekusimba kwavo kwepamusoro uye kugona kutsungirira kupisa kwakanyanya uye kupfeka. Pamusoro pezvo, tinoshandisa mishonga yakakosha kudzivirira masisitimu edu kubva ku ngura nekuora. Aya masisitimu ari nyore kuchengetedza nekuti isu takaagadzirisa.

Q235A kabhoni simbi ine yakakwirira magineti zvivakwa uye inodhura zvakanyanya kupfuura simbi isina tsvina. Inowanzoshandiswa mumakemikari epamusoro kurapwa. Chinangwa chekusviba kurapa ndechekugadzira firimu reoxyde pamusoro pesimbi kuti iparadzanise kubva kumhepo uye kupa yakasimba anti-rust barriers.

Vamwe vatengi vane hanya nezve oxide layer inokanganisa simende. Kuti tive nechokwadi chekuchengetedzeka kwezvinhu zvese zvesimende pamusoro, takaita yakasarudzika yekupukuta kurapa paQ235A kabhoni simbi.

Iyo aluminium alloy formwork magineti ine aruminiyamu alloy formwork uye yakamisikidzwa magineti block. Kutenda kune yakasarudzika tekinoroji yekugadzirisa, iyo aluminium alloy formwork yakasimba zvakanyanya. Inopa njodzi diki yekukotama, kurira, kana kuputika zvichienzaniswa nesimbi kana simbi isina tsvina. Uye zvakare, aluminium alloy ine yakanakisa kuenderana uye kugadzikana. Iyo yakaderedzwa huremu hweformwork inoitawo kuti zvive nyore kubata uye kushandisa.

Stainless simbi formwork magineti anosanganisira Stainless simbi formwork uye akamisikidzwa magineti blocks. Ikareruka uye iri nyore kushandisa neruoko rwerobhoti.

Honsen Magneticsine nhaka yakapfuma yeanopfuura makore gumi mukugadzira nekutengesa kwePermanent Magnets, Magnetic Components uye Magnetic Merchandise. Vashandi vedu vane hunyanzvi vane mutsara wekugadzira wakakwana, maitiro ekubata senge machining, musangano, welding uye jekiseni kuumba. Mukurumbira wedu wakavakirwa pamitengo inonzwisisika, zvigadzirwa zvemhando yepamusoro uye pfungwa dzevatengi-centric, uye inonakidzwa nemukurumbira wepamusoro muEurope neAmerica.

- Kupfuurisa10 makore ruzivo mune zvechigarire magineti zvigadzirwa indasitiri

- Pamusoro5000m2 fekitari ine200advanced Machines

- Iva amutsara wekugadzira wakakwanakubva mukugadzira, kubatanidza, welding, jekiseni kuumba

-Iva neiyo yakasimba R&D timu inogona kupa yakakwanaOEM & ODM sevhisi

-Vashandi vane unyanzvi & kuenderera mberi nekuvandudza

- Isuchetekuendesa kunze zvigadzirwa zvinokwanisa kune vatengi -

-Kukurumidza kutumira & kutumirwa kwepasirese

- ShumiraONE-KUMIRA-SOLUTION chengetedza kutenga kwakanaka uye kusingadhuri

-24-awaonline sevhisi nemhinduro yekutanga-nguva

Chinangwa chedu chakasimba ndechekupa vatengi rubatsiro rwemberi uye zvigadzirwa zvitsva, zvemakwikwi, nekudaro tichisimbisa chinzvimbo chedu mumusika. Tichitungamirwa nekubudirira kwakawanikwa mumagineti echigarire uye zvikamu, tarisiro yedu iri pakukura kuburikidza nekufambira mberi kwetekinoroji uye kuwana misika isina kushandiswa. Dhipatimendi rakasimba reR&D, rinotungamirwa nainjiniya mukuru, rinowedzera kugona-mumba, rinokudziridza hukama hwevatengi, uye rinofanotaura nenzira kwayo mafambiro emusika. Bato rakazvimiririra rinotarisisa zvirongwa zvepasi rese, richichengetedza runyararo rwebasa rekutsvagisa ririkuenderera mberi.

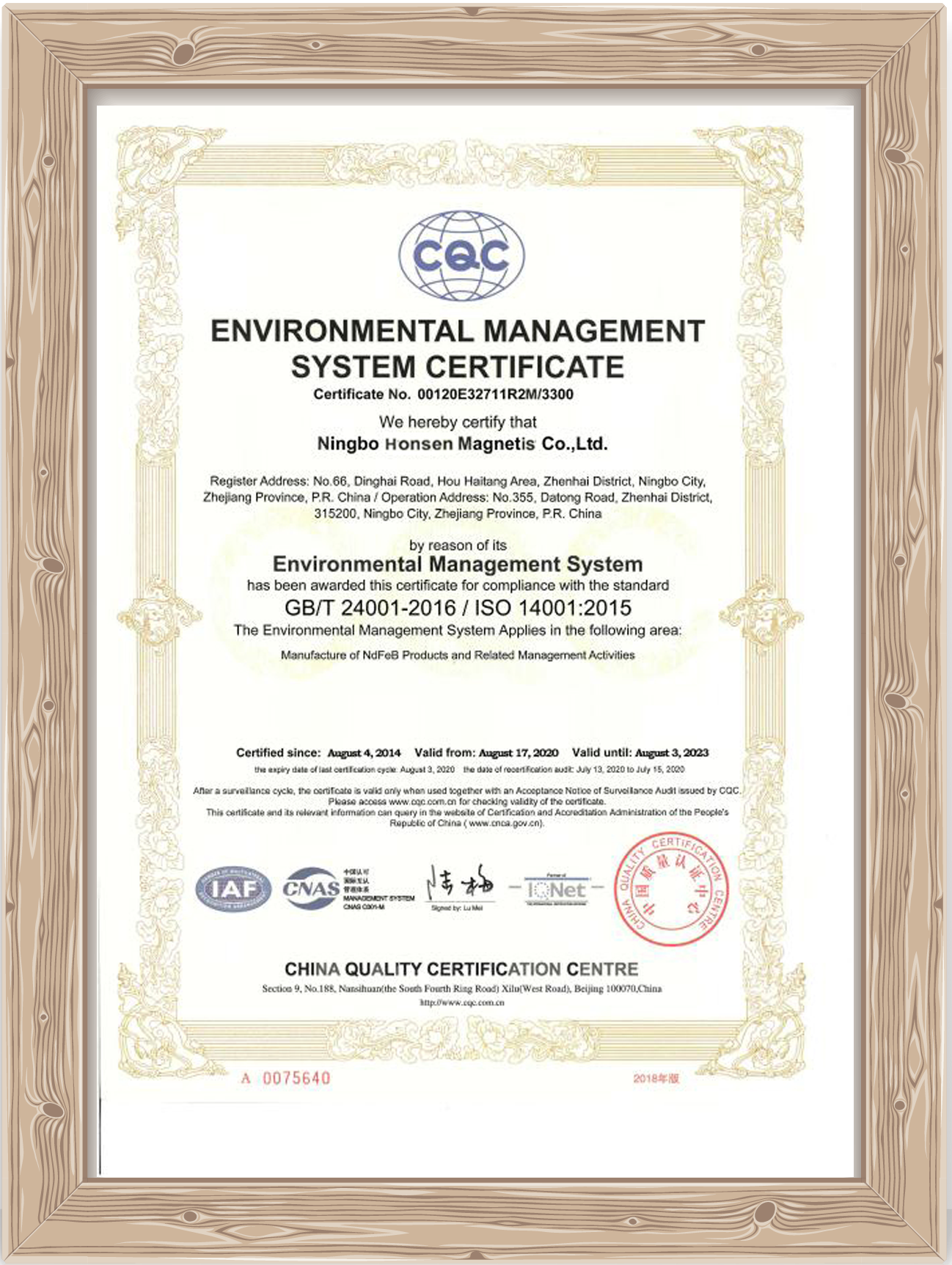

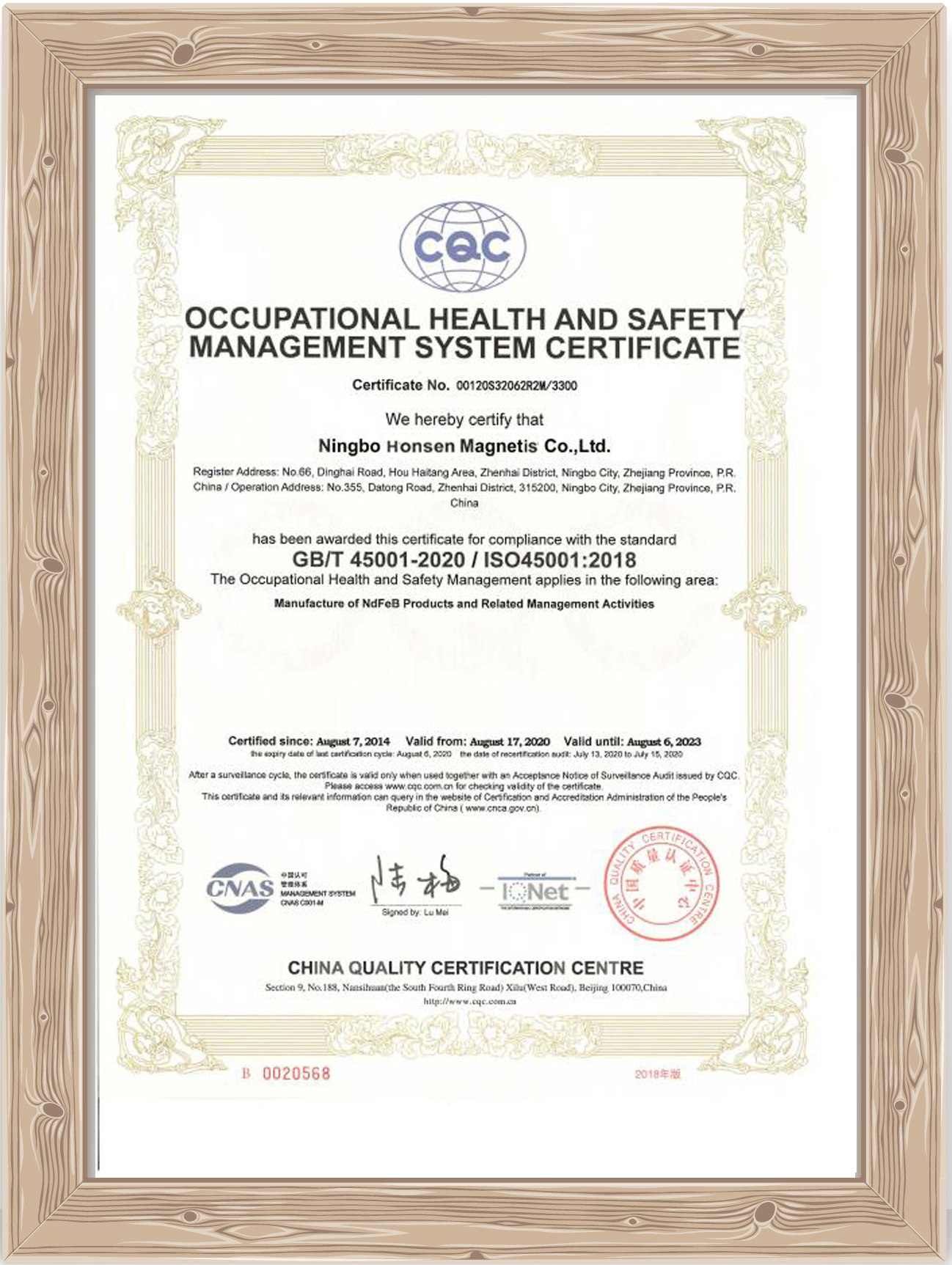

Hunhu manejimendi ndiyo nheyo yekambani yedu kukosha. Isu tinotenda zvakasimba kuti mhando ndiyo ropa rehupenyu uye kambasi yebhizinesi. Kuzvipira kwedu kunopfuura nzira dzechinyakare kune manejimendi emhando - zvakarukwa mukushanda kwedu. Nekushandisa nzira iyi, tinovimbisa kuti zvigadzirwa zvedu zvinogara zvichisangana nekupfuura zvinodiwa nevatengi vedu, tichiisa mabhenji matsva mukugutsikana.

Kambani yedu yakadzika midzi mukutarisira kwemhando. Isu tinotenda kuti mhando haisi pfungwa chete, asi simba rehupenyu uye inotungamira musimboti wesangano redu. Maitiro edu anodarika pamusoro - isu tinobatanidza zvisina musono hurongwa hwedu hwekutonga mumabasa edu. Kuburikidza nemaitiro aya, tinoona kuti zvigadzirwa zvedu zvinosangana uye zvinodarika zvinotarisirwa nevatengi vedu, zvichiratidza kuzvipira kwedu kuita zvakanaka.