Chii chinonzi Magnet?

Magineti chinhu chinoshandisa simba riri pachena pachiri pasina kubatana kwenyama nezvimwe zvinhu.Simba iri rinonzi magnetism.Magnetic simba rinogona kukwezva kana kudzinga.Zvizhinji zvinozivikanwa zvinhu zvine simba remagineti, asi simba remagineti mune izvi zvinhu idiki kwazvo.Kune zvimwe zvinhu, simba remagineti rakakura kwazvo, saka zvinhu izvi zvinonzi magineti.Nyika pachayo imagnetti hombe.

Pane mapoinzi maviri pane ese magineti uko simba remagineti rakakura.Anozivikanwa semapango.Pane rectangular bar magineti, mapango akatarisana.Vanodaidzwa kunzi North Pole kana kuti North Pole, uye South Pole kana maodzanyemba-seking.

Magneti anogona kungogadzirwa nekutora magineti iripo wokwesha simbi nayo.Ichi chidimbu chesimbi chiri kushandiswa chinofanira kuramba chichikwizwa munzira imwe.Izvi zvinoita kuti maerekitironi muchidimbu chesimbi chitange kutenderera munzira imwe chete.Magetsi aripo anokwanisawo kugadzira magineti.Sezvo magetsi ari kuyerera kwemaerekitironi, kana maerekitironi enhare achifamba muwaya anotakura zvakafanana nemaerekitironi anotenderera nepakati peatomu.Iyi inonzi electromagnet.

Nekuda kwekurongeka kwadzo maerekitironi, simbi nickel, cobalt, iron, uye simbi inoita magineti akanaka kwazvo.Masimbi aya anogona kugara magineti zvachose kana angove magineti.Saka kutakura zita rekuti magineti akaomarara.Zvakadaro masimbi aya nemamwe anogona kuita semagineti kwekanguva kana aiswa pachena kana kusvika pedyo negineti yakaoma.Vanobva vatakura zita rekuti magineti manyoro.

Magnetism Inoshanda Sei

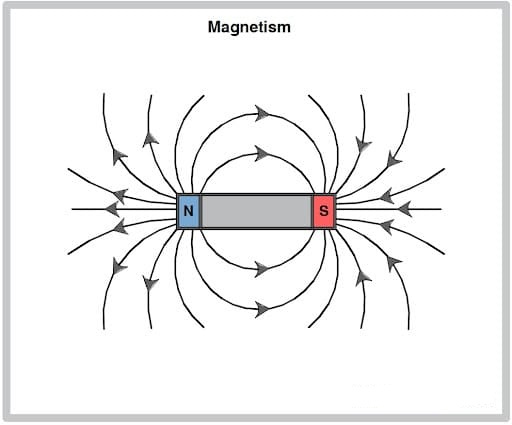

Magnetism inoitika apo tunhu tudiki tunonzi maerekitironi tinofamba neimwe nzira.Nyaya yose inoumbwa nezvikamu zvinonzi maatomu, ayo anoumbwa nemaerekitironi nezvimwe zvikamu, zvinova manyuturoni nemapurotoni.Maerekitironi aya anowanzo tenderera nechepakati, iyo ine zvimwe zvikamu zvataurwa pamusoro apa.Simba diki remagineti rinokonzerwa nekutenderera kwemaerekitironi aya.Mune zvimwe zviitiko, maerekitironi akawanda ari muchinhu anotenderera achienda kune rimwe divi.Mhedzisiro yeaya magineti madiki masimba kubva kumaerekitironi igineti hombe.

Kugadzirira Poda

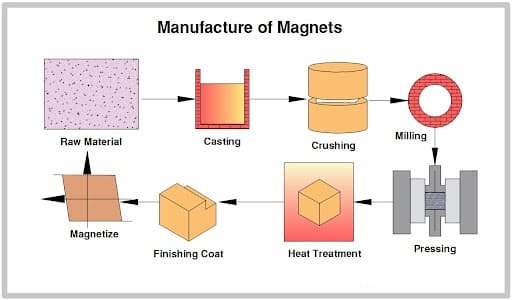

Huwandu hwakakodzera hwesimbi, boron, uye neodymium zvinodziyirwa kuti dzinyunguduke pasi pevacuum kana muchoto chekunyungudika chemukati uchishandisa gasi inert.Iko kushandiswa kwevacuum ndeyekudzivirira kuita kwemakemikari pakati pezvinhu zvinonyunguduka nemhepo.Kana iyo yakanyungudutswa yakanyungudutswa yatonhora, inotyoka nekupwanywa kuita tumarata tudiki.Mushure mezvo, zvimedu zviduku zvinoputika uye zvinopwanyika muhupfu hwakatsetseka hunobva pa3 kusvika ku7 microns muhupamhi.Iyo hupfu huchangobva kuumbwa hunoita zvakanyanya uye hunokwanisa kukonzera kupisa mumhepo uye inofanira kuchengetedzwa kubva pakusangana neokisijeni.

Isostatic Compaction

Maitiro e isostatic compaction anonziwo kudzvanya.Iyo simbi yehupfu inotorwa uye yakaiswa muforoma.Mold iyi inodaidzwa zvakare kuti kufa.Kuti zvinhu zvehupfu zvienderane nehupfu simba remagineti rinoitwa, uye panguva iyo simba remagineti riri kushandiswa, makondohwe e hydraulic anoshandiswa kuimanikidza zvachose kusvika mukati me 0.125 inches (0.32 cm) yezvakarongwa zvayo. ukobvu.Kudzvinyirira kwakanyanya kunoshandiswa kazhinji kubva ku10,000 psi kusvika ku15,000 psi (70 MPa kusvika 100 MPa).Mamwe magadzirirwo uye maumbirwo anogadzirwa nekuisa zvinhu mumudziyo unovharwa nemhepo usati wazvidzvanya muchimiro chaunoda nemhepo yegesi.

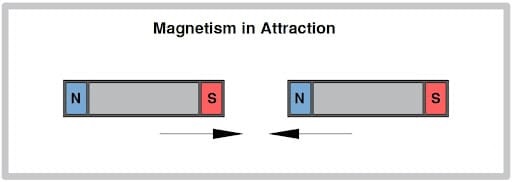

Zvizhinji zvezvinhu zvinotora semuenzaniso, huni, mvura, uye mhepo zvine magineti zvimiro izvo zvisina kusimba zvakanyanya.Magnets anokwezva zvinhu zvine aimbova simbi zvakasimba.Anokwezva kana kudzinga mamwe magineti akaomarara kana aswededzwa pedyo.Izvi zvinokonzerwa nekuti magineti ese ane mapango maviri akatarisana.Matanda ekumaodzanyemba anokwezva matanda ekuchamhembe emamwe magineti, asi anodzinga mamwe mapango ekumaodzanyemba uye zvinopesana.

Manufacturing Magnets

Nzira inonyanya kushandiswa mukugadzira magineti inonzi powder metallurgy.Sezvo magineti achibatanidza zvinhu zvakasiyana, maitiro ekugadzira iwo akasiyana uye akasiyana ega.Semuenzaniso, magineti emagetsi anogadzirwa uchishandisa simbi yekukanda matekiniki, nepo anochinjika anogara magineti anogadzirwa mumaitiro anosanganisira epurasitiki extrusion umo mbishi inosanganiswa mukupisa isati yamanikidzwa kuburikidza nekuvhura pasi pekumanikidzwa kwakanyanya.Pazasi pane maitiro ekugadzira magineti.

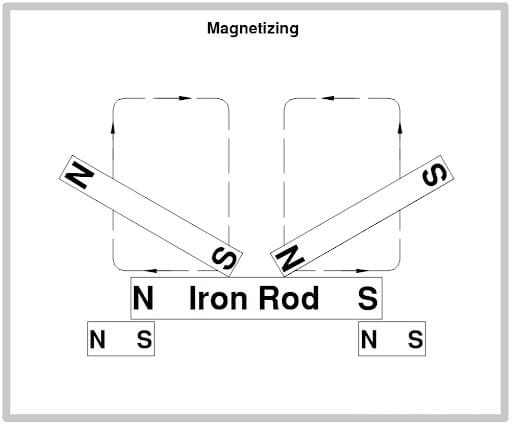

Ese akakosha uye akakosha maficha ekusarudzwa kwemagineti anofanirwa kuunzwa pasi pekukurukurwa neaviri einjiniya nezvikwata zvekugadzira.Iyo magnetizing maitiro pakugadzira magineti, kusvika panguva ino, zvinhu chidimbu chesimbi yakamanikidzwa.Kunyangwe yaiiswa pane simba remagineti panguva yekutsikirira isostatic, simba racho harina kuunza magineti kuzvinhu, rakangoisa mutsara wakasununguka hupfu.Chidimbu chinounzwa pakati pemapango emagetsi emagetsi akasimba uye obva atariswa munzira yakanangana nemagnetization.Mushure mekunge magetsi emagetsi asimbiswa, simba remagineti rinobatanidza magineti mukati mechinhu, zvichiita kuti chidimbu chive magineti yakasimba kwazvo.

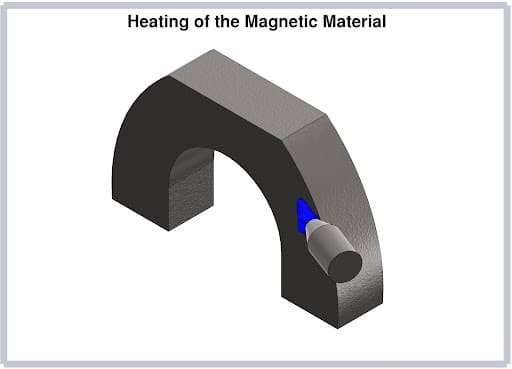

Kupisa Kwezvinhu

Mushure mekuita kwe isostatic compaction iyo slug yehupfu simbi inoparadzaniswa kubva pakufa uye inoiswa muchoto.Sintering (Sintering) inzira kana nzira yekuwedzera kupisa kusimbi dzakatsikirirwa kuti ishanduke kuita zvidimbu zvesimbi zvakasanganiswa.

Iyo sintering process inonyanya kuumba matanho matatu.Munguva yekutanga nhanho maitiro, iyo yakamanikidzwa zvinhu inodziirwa patembiricha yakadzika kwazvo kuitira kudzinga hunyoro hwese kana zvinhu zvese zvinosvibisa zvingave zvakavharirwa panguva yeisostatic compaction process.Muchikamu chechipiri chekupisa, pane kukwira kwekushisa kusvika pa70-90% yealloy's melting point.Tembiricha inozoitwa ipapo kwechinguva chemaawa kana mazuva kuitira kuti twunhu twudiki twuenderane, kubatanidza uye kubatanidza.Danho rekupedzisira rekunyunguduka ndipo parinotonhodzwa zvishoma nezvishoma mukuwedzera tembiricha inodzorwa.

Kuwedzeredza Kwezvinhu

Mushure mekupisa kunouya nzira yekuisa annealing.Apa ndipo apo iyo sintered zvinhu inopinda imwe nhanho nhanho inodzorwa kudziyisa uye kutonhora maitiro kuitira kurasa chero kana zvese zvakasara zvinonetsa zvinosara mukati mechinhu uye kuita kuti ive yakasimba.

Magnet Kupedzisa

Magineti ari pamusoro akacheneswa ane imwe nhanho kana dhigirii rekugadzira, kubva pakuakuya akatsetseka uye anoenderana kana kugadzira zvikamu zvidiki kubva mumabhuroko magineti.Izvo zvinhu zvinogadzira magineti zvakanyanya kuoma uye brittle (Rockwell C 57 kusvika 61).Naizvozvo chinhu ichi chinoda mavhiri edhaimani kune ekuchekesa maitiro, anoshandiswawo kune abrasive mavhiri ekukuya maitiro.Nzira yekucheka inogona kuitwa nehupamhi hwepamusoro uye kazhinji inobvisa kudiwa kwekuita kwekukuya.Maitirwo ataurwa pamusoro apa anoda kuitwa nekuchenjerera kuti aderedze kucheka nekutsemuka.

Pane zviitiko apo chimiro chekupedzisira magineti kana chimiro chinonyatso gadzirisa nedhaimani vhiri rekukuya sechingwa.Mhedzisiro yechimiro chekupedzisira inounzwa kupfuura vhiri rekukuya uye vhiri rekukuya rinopa chiyero chakarurama uye chakanyatsojeka.Iyo annealed product iri padyo neyakapedzwa chimiro uye zviyero zvekuti inoda kugadzirwa.Pedyo net shape izita rinowanzopihwa kune ichi chimiro.Yekupedzisira uye yekupedzisira machining process inobvisa chero yakawandisa zvinhu uye inopa yakatsetseka yepamusoro painodiwa.Pakupedzisira kuitira kuti uvhare pamusoro pechinhu chacho chinopiwa chifukidzo chekudzivirira.

Magnetizing Process

Magnetizing inotevera maitiro ekupedzisa, uye kana maitiro ekugadzira aitwa, magineti inoda kuchaja kuitira kuti ibudise yekunze magineti.Kuti uite izvi, solenoid inoshandiswa.Solenoid ihumburumbira mugomba umo magineti akasiyana saizi uye maumbirwo anogona kuiswa kana aine zvigadziriso solenoid inogadzirwa kuti ipe akasiyana magineti mapatani kana dhizaini.kuitira kudzivirira kubata uye kuunganidza aya magineti ane simba mumamiriro avo emagnetized magungano makuru anogona kubatwa nemagineti. .Kufunga kunofanirwa kuitwa kune magnetizing ndima inodiwa, iyo yakakura kwazvo.

Nguva yekutumira: Jul-05-2022